This critical trunk water main feeds more than 6000 properties within the greater Coolum area, along with the Sunshine Coast Airport expansion project.

| PROJECT OVERVIEW | Unitywater experienced two (2) major failures on a critical trunk water main (Stage #1) that runs along Finland Rd, Bli Bli in January 2019. This critical trunk water main feeds more than 6000 properties within the greater Coolum area, along with the Sunshine Coast Airport expansion project. In order to ensure the security of the water supply to these customers, Unitywater installed an emergency overland land main (Stage #2) to bypass the 2.2km section of main which encompassed the two failures. Unitywater has since undertaken a condition assessment of this trunk main (Stage #3) and it has been determined it is no longer fit for purpose. Stage #4 is: 1> Design and construction of approximately 2.2km of OD610 SKCL trunk water main to replace the existing failed trunk water main along Finland Rd, Bli Bli. Includes all isolation valves, scour valves and air valves. 2> Removal and disposal of the overland emergency trunk main which runs from David Low Way to the Suncoast Treatment Plant access road on Finland Rd, Bli Bli |

| CLIENT | Unitywater |

| LOCATION | Finland Rd, Bli Bli Queensland |

| INDUSTRY SECTOR | Water (Rural) |

| INFRASTRUCTURE | Water Mains |

| CONTRACT VALUE | Stage #1 = $0.23m Stage #2 = $1.25m Stage #3 = $0.23m Stage #4 = $7.8m |

| DATES | Stage #2 – 1.5 months. This included all design, procurement, and construction of the full bypass main. All at once. Stage #3 – #4 – Design and Procurement – 19 weeks from Feb 21 to June 21 – Dewatering Trials, installation of PFAS reinjection system and tanks – 19 weeks from July 21 to September 21 – Construction – Commenced October 21. There have been 2 no. floods and is now in standdown. Proposed Completion December 23. |

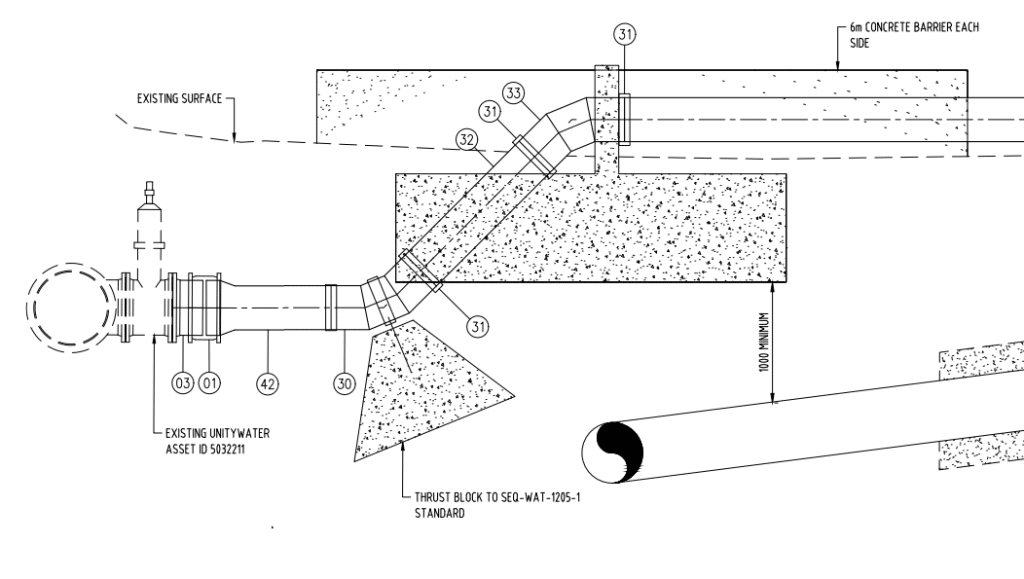

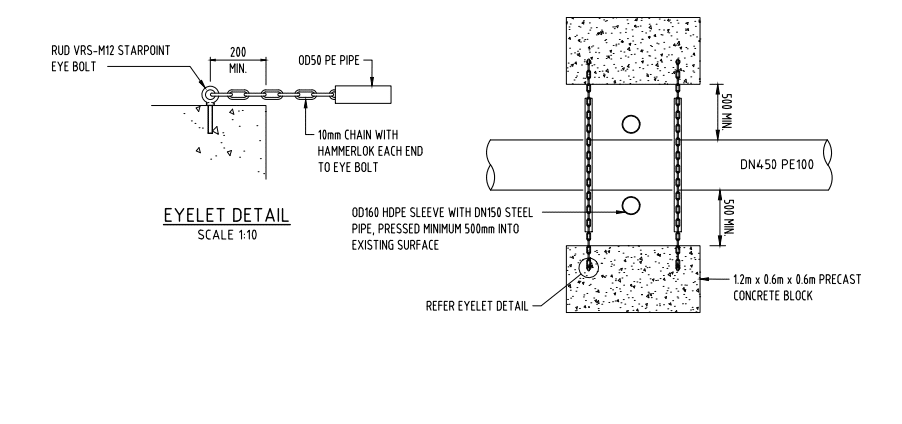

| LESSONS LEARNT AND SMART INNOVATIONS | Stage #2 – The use of PCB’s for thrust blocks so they can be removed at a later date Stage #2 – The floatation designs used to avoid the pipe from floating or being washed away.  Stage #4 – The use of existing infrastructure (i.e. the OD710 PE water main which was disused) to transport extracted PFAS-contaminated groundwater from the trench to the proposed storage tank to the north of the project. This avoided the installation of long lengths of lay flat hose and additional pumping. The saving on pumping and fuel costs is in the order of $0.4m over the course of the project. Stage #4 – With the use of space-proofing and changing construction staging, the design was able to avoid the removal of the existing main for the greater majority of the new pipeline alignment. This produced savings in the order of $0.5m. |